3D Laser Documentation for BIM, MEP, and Industrial Facilities

High-accuracy laser scanning and point cloud data to support BIM modeling, design coordination, and as-built documentation

3D Laser Documentation

3D laser documentation is an advanced reality capture method used to create highly accurate digital representations of existing facilities and structures. Using high-resolution laser scanners, OmniVueNDT captures millions of spatial data points to generate detailed 3D point clouds that reflect actual site conditions.

These point clouds serve as the foundation for Building Information Modeling (BIM), as-built documentation, and design coordination across industrial, commercial, and infrastructure projects.

Laser Scanning and Data Registration

The laser scanning process begins with on-site data acquisition using multiple scan positions to capture complete coverage of the facility. Registration targets such as spheres or checkerboards are placed strategically throughout the scan area to align individual scans into a single, unified coordinate system.

Registered scans are combined to create a superimposed 3D point cloud, allowing accurate spatial relationships between structural, architectural, and mechanical elements to be visualized and measured.

BIM, MEP, and Design Applications

3D laser documentation supports a wide range of BIM and design applications, including civil, architectural, structural, construction, plant, and MEP (mechanical, electrical, and plumbing) workflows. The point cloud environment enables real-time measurement, clash identification, and virtual inspection of piping, utilities, equipment, and structural components.

Laser-scanned data can be used for pipe and utility design or re-design, construction coordination, and verification of existing conditions prior to modification or expansion.

Data Extraction and Deliverables

From the registered point cloud, multiple deliverables can be generated to support project needs. These may include 3D models, 2D floor plans, elevation views, and virtual walkthroughs. Accurate measurements can be taken directly within the digital environment, and data can be exported in commonly used formats such as DXF or DWG for integration into downstream design platforms.

This approach allows teams to work from a reliable digital reference without repeated site visits.

Advantages of 3D Laser Documentation

Key advantages of laser-based 3D documentation include rapid data acquisition, high spatial accuracy, real-time measurement capabilities, and flexible data export options. The technology supports efficient collaboration and reduces uncertainty during planning, design, and construction activities.

Important Considerations

3D laser documentation captures existing conditions at the time of scanning. While highly accurate, results depend on access, line of sight, and site conditions. Laser scanning does not replace engineering judgment, and final design decisions should be made by qualified professionals.

Need Accurate As-Built Documentation or BIM Data?

3D laser documentation provides reliable digital insight to support planning, coordination, and facility management.

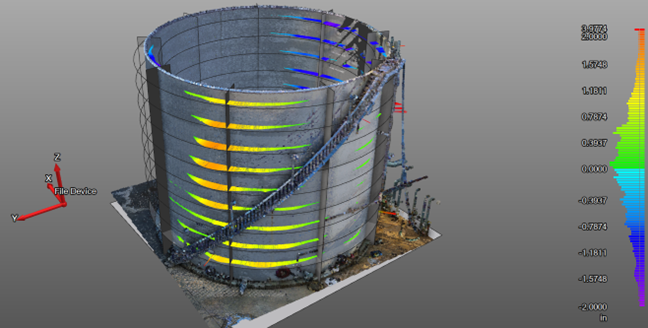

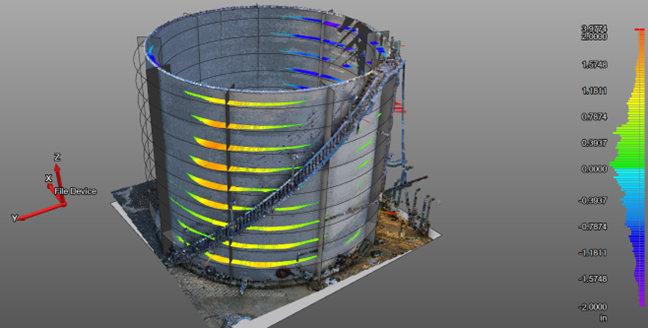

Industrial storage tank documented using 3D laser scanning technology.

High-resolution 3D point cloud model created from laser scan data.

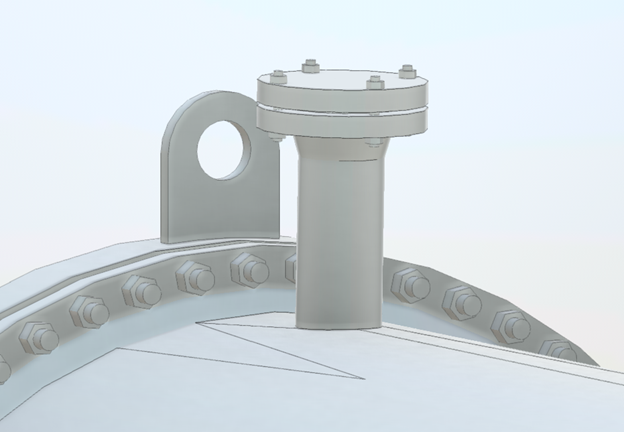

Detailed BIM model generated from point cloud for design coordination.

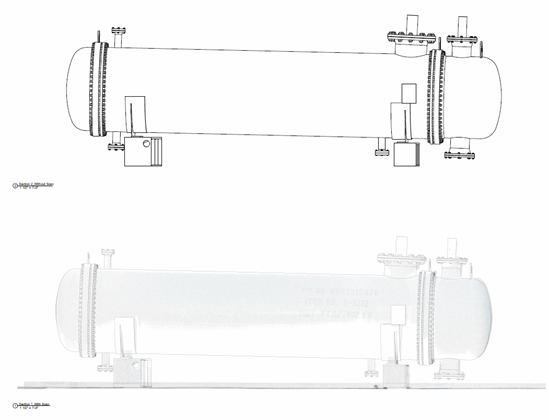

Fabrication-ready CAD drawings exported from laser scan data.