Concrete Scanning on Post-Tension (PT) Beams and Girders

Non-destructive GPR scanning to help identify embedded reinforcement before drilling, cutting, or coring

Concrete Scanning on Post-Tension (PT) Beams and Girders

Concrete scanning on post-tension (PT) beams and girders is performed to help identify embedded reinforcement prior to drilling, cutting, or coring. OmniVueNDT uses ground penetrating radar (GPR) to non-destructively locate post-tension tendons and reinforcing steel within concrete beams to support safer construction activities.

Before any drilling, cutting, or coring is performed, concrete structures must be scanned to help avoid damaging embedded reinforcement.

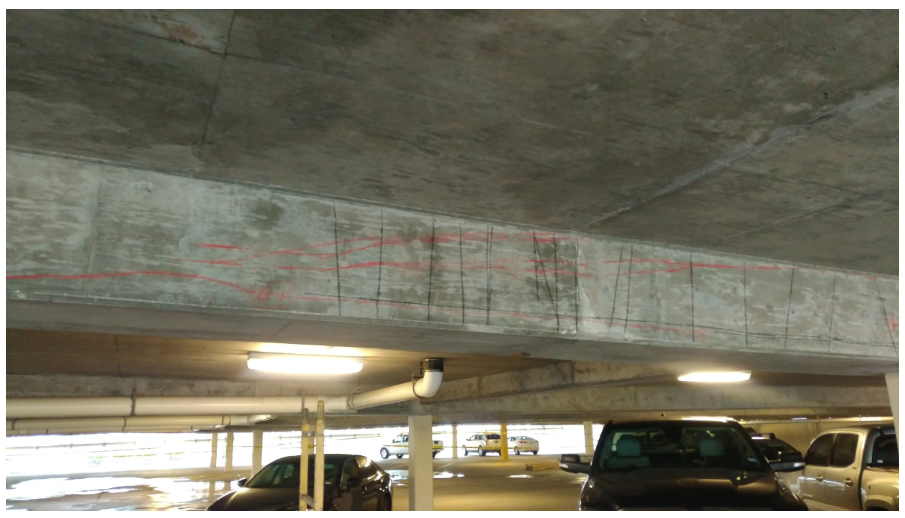

Concrete support beam with GPR scan markings showing post-tension cable and rebar locations.

Why PT Beams and Girders Require Special Attention

Post-tension beams and girders are critical structural elements that often carry concentrated loads and experience higher stress levels than flat slabs. Reinforcement within these members is frequently congested, and access for scanning may be limited to specific faces or orientations.

Because of these conditions, accidental damage to post-tension tendons or reinforcing steel within beams or girders can have a greater structural impact, making pre-construction scanning an important step for risk mitigation.

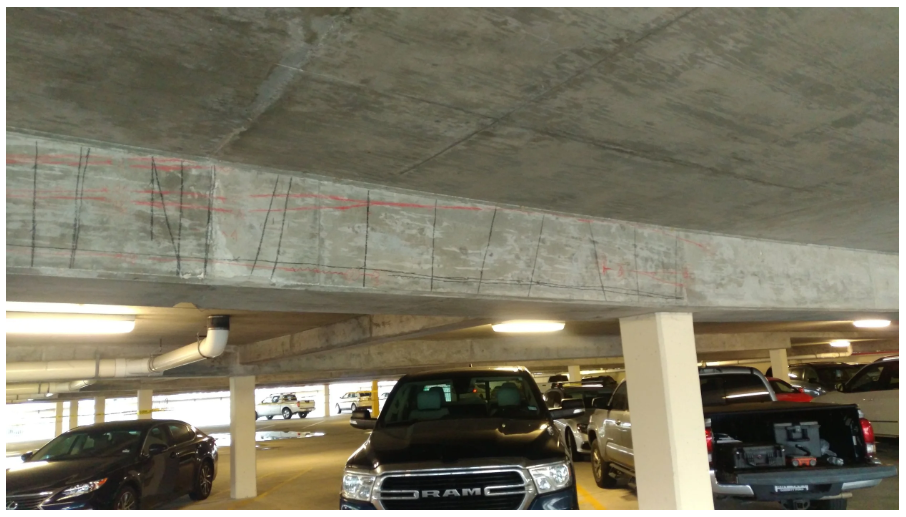

Post-tension beam scanned from multiple accessible surfaces to map complete reinforcement profile.

GPR Scanning Methods for PT Beams and Girders

There are two primary GPR scanning methods used for post-tension beams and girders, depending on project needs and documentation requirements.

Real-Time (2D) GPR Scanning

In real-time scanning, the field technician conducts the GPR survey in 2D mode, collecting multiple 1.5D radargrams as the antenna is moved along accessible beam surfaces. The scan results are interpreted in the field, and detected reinforcement is physically marked on the surface of the concrete beam.

This scanning approach provides immediate field guidance and is commonly used when drilling, cutting, or coring locations need to be identified efficiently.

Grid-Based (3D) GPR Scanning

For projects requiring enhanced visualization or documentation, GPR scanning may be performed in 3D mode. In this approach, the scan area is established by the client or their field representative, and the radar survey is conducted using a formal 3D grid pattern, typically with scan intervals ranging from 2 to 6 inches in both latitude and longitude directions.

The final product of this method is a digital model of the concrete beam, which may indicate reinforcement patterns and post-tension cable profiles. This type of interpretation may be used to obtain as-built information and to support additional calculations when required.

Detailed scan markings showing post-tension cable profile and steel rebar layout on concrete beam for structural repair planning.

Important Considerations

Ground penetrating radar is a non-destructive, interpretive technology, and results may vary depending on concrete composition, reinforcement density, moisture conditions, and site accessibility. GPR scanning does not replace structural engineering evaluation, and final decisions regarding drilling, cutting, or coring locations remain the responsibility of the project team.

OmniVueNDT emphasizes clear communication of findings, confidence levels, and limitations to support informed decision-making and risk mitigation.

Planning to Drill, Core, or Cut a PT Slab?

Early concrete scanning helps reduce risk, prevent costly damage, and improve jobsite safety.