Concrete Scanning Services

Non-destructive scanning to locate reinforcement, post-tension cables, and embedded elements before you cut, core, or drill.

Advanced Concrete Scanning with Ground Penetrating Radar

Concrete scanning is a critical step before any drilling, coring, cutting, anchoring, or structural modification work is performed. OmniVueNDT utilizes high-frequency Ground Penetrating Radar (GPR) technology to non-destructively locate and map embedded elements within concrete structures. These elements may include post-tension cables, reinforcing steel (rebar), conduits, voids, slab thickness variations, and other structural components that are not visible from the surface.

By identifying internal reinforcement and structural features prior to intrusive work, concrete scanning significantly reduces the risk of accidental damage, costly repairs, structural compromise, and serious safety hazards. Striking a post-tension tendon, for example, can result in immediate safety concerns and extensive structural impact. GPR scanning provides project teams with the information necessary to make safe, informed decisions.

OmniVueNDT offers both real-time (2D) scanning and advanced grid-based (3D) GPR imaging depending on project requirements. Real-time scanning allows technicians to interpret data in the field and mark reinforcement locations directly on the concrete surface for immediate guidance. For projects requiring enhanced documentation or as-built verification, 3D grid scanning produces a digital representation of the scanned area, providing a detailed visualization of reinforcement layout, tendon profiles, and slab characteristics.

Our concrete scanning services are used across commercial, industrial, infrastructure, and residential projects. From parking structures and elevated slabs to beams, girders, foundations, and industrial facilities, OmniVueNDT delivers reliable subsurface data that supports safe construction practices and structural integrity.

Whether the objective is risk mitigation, structural evaluation, or documentation for planning and engineering analysis, our GPR-based concrete scanning solutions provide accurate, non-destructive insight into what lies beneath the surface.

Concrete Scanning with GPR in 3D

Concrete scanning with 3D Ground Penetrating Radar (GPR) is performed by collecting subsurface data in a formal grid pattern to generate layered depth slices and three-dimensional radar models. The system transmits high-frequency electromagnetic pulses into the concrete surface, and reflected signals are processed to determine the depth, spacing, and configuration of embedded reinforcement, post-tension cables, conduits, and slab thickness variations.

3D GPR scanning is commonly used when enhanced visualization, digital documentation, or as-built verification is required. This method provides comprehensive structural insight for engineering analysis, renovation planning, forensic investigation, and projects requiring detailed subsurface mapping beyond real-time surface markings.

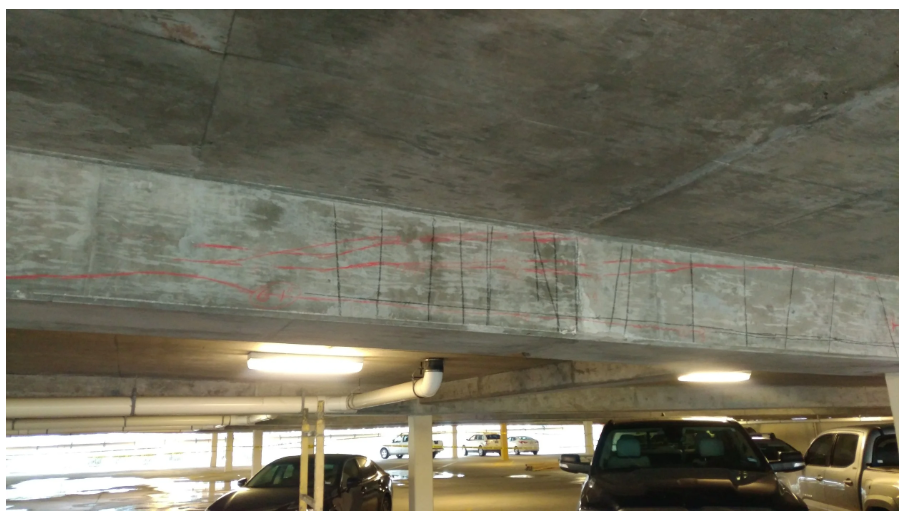

Concrete Scanning on Post-Tension (PT) Beams and Girders

Concrete scanning on post-tension (PT) beams and girders is performed to identify the profile, depth, and alignment of post-tension tendons and reinforcing steel within structural members. High-frequency GPR is applied to accessible surfaces of the beam or girder to detect embedded elements and interpret their spatial relationship within the structure.

PT beam and girder scanning is routinely used prior to coring, cutting, anchoring, or structural modification. This non-destructive method helps prevent tendon strikes, supports structural repair planning, and provides reliable data for retrofit design and forensic evaluation of existing structural systems.

Concrete Scanning on a Post-Tension (PT) Slab

Concrete scanning on post-tension slabs utilizes high-frequency GPR to locate tendon layouts, reinforcement spacing, embedded utilities, and slab thickness variations. The radar system emits electromagnetic waves into the slab surface and measures reflected signals to determine the depth and configuration of internal components.

PT slab scanning is a widely used non-destructive testing method performed prior to drilling, coring, saw cutting, or anchor installation. It is commonly applied for renovation projects, mechanical and plumbing penetrations, quality assurance in new construction, and verification of structural conditions in existing facilities.

Concrete Scanning with GPR in 3D

3D grid-based GPR scanning provides enhanced visualization of embedded reinforcement and structural components within slabs and elevated decks. By scanning in a systematic grid pattern, we generate layered depth slices and detailed subsurface maps that assist with engineering evaluation, structural planning, and documentation.

This method is ideal for projects requiring comprehensive data, structural investigations, or digital reporting beyond surface markings.

Applications Include:

Slab reinforcement mapping

Structural condition evaluation

As-built documentation

Engineering analysis support

Concrete Scanning on Post-Tension (PT) Beams and Girders

Post-tension beams and girders require precise identification of tendon profiles and reinforcement layouts prior to modification. OmniVueNDT scans accessible surfaces to map cable paths, rebar placement, and structural elements to help prevent tendon strikes during coring or cutting operations.

Our scanning approach supports structural repair planning, retrofits, and safe penetration design.

Applications Include:

Tendon profiling

Beam coring and cutting layout

Structural modification planning

Repair and retrofit support

Concrete Scanning on Post-Tension (PT) Slabs

PT slabs demand careful evaluation before any intrusive work is performed. Our GPR scanning services identify cable locations, reinforcement spacing, slab thickness, and embedded utilities to help contractors safely core, drill, or anchor into slab systems.

Real-time scanning allows for accurate surface marking, while 3D documentation is available for projects requiring advanced reporting.

Applications Include:

Safe coring and drilling

Anchor placement

Mechanical, electrical, and plumbing penetrations

Structural slab evaluation

Why Concrete Scanning Matters

Unidentified reinforcement and post-tension systems present serious safety and structural risks. Accidental strikes can cause structural damage, project delays, costly repairs, and potential injury.

Concrete scanning provides:

Risk mitigation before intrusive work

Increased jobsite safety

Reduced repair and downtime costs

Structural insight without destructive testing

Accurate planning for modifications and renovations

By utilizing non-destructive testing technology, OmniVueNDT helps project teams build and modify with confidence.

Protect Your Project Before You Penetrate the Surface

Whether you’re preparing for coring, cutting, anchoring, or structural modifications, OmniVueNDT delivers reliable subsurface data to support safe execution.